3 Signs You Need Hydraulic Repairs

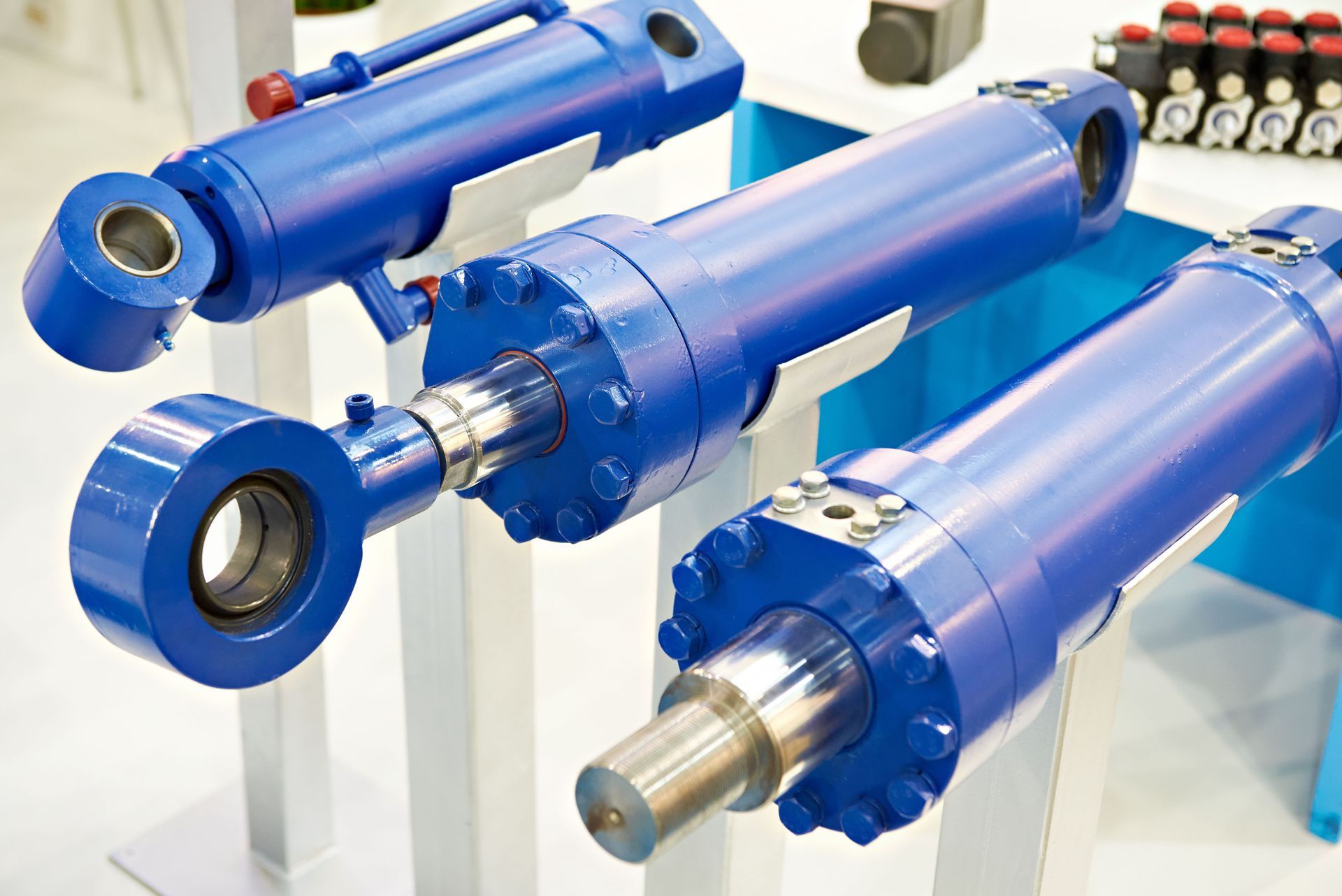

Hydraulics are an integral part of many machines and equipment. From lifts to presses to industrial doors, hydraulics provide the power, motion, and efficiency needed for smooth operation. But as with any mechanical system, hydraulic components wear down over time.

When hydraulics start to fail, it's important to recognize the signs, so you can schedule hydraulic repairs promptly. This prevents further issues and keeps your equipment running safely and productively. Read on to learn about three telltale indicators that you need hydraulic service.

1. Leaks

One of the most obvious signs of hydraulic troubles is leaking fluid. Check around cylinders, pumps, valves, and hoses for evidence of leaks. You may notice puddles on the floor, dripping oil, or spray from a pinhole leak.

Leaks mean seals are compromised and contaminants can enter the system, causing extensive damage if left unaddressed. Even small leaks reduce system pressure and performance. Don't ignore any hydraulic fluid leaks - have an expert assess and perform hydraulic repairs as needed.

2. Noisy Operation

When hydraulic systems are operating optimally, they run quietly and smoothly. So loud whining, banging, or hissing noises can signal issues needing attention. Cavitation, aeration, and turbulence within hydraulic fluid lead to noise as air bubbles are compressed. According to the Multidisciplinary Digital Publishing Institute, 70% of failures are caused by contamination in hydraulic systems.

Excessive noise can also indicate worn pumps or valves. It could also indicate obstruction somewhere in the system. Seek out hydraulic repairs to identify and resolve the root cause of any unusual noises.

3. Loss of Power or Speed

Hydraulics provide the muscle to lift heavy loads or move components at certain speeds. A loss of power or speed often indicates worn parts or low hydraulic fluid levels. Cylinders may extend slower than normal or not reach full stroke.

Lifts may struggle with the weight they used to handle easily. Presses or clamps may lack normal pressure. With less force being generated, productivity and safety are compromised. Schedule prompt hydraulic service to determine why your equipment lacks its normal power and performance.

Catching hydraulic problems early allows for repairs before catastrophic failure occurs. This minimizes downtime and expensive damage. At the first sign of trouble, don't hesitate to call in hydraulic repair professionals. They have the expertise to properly diagnose problems and get your vital hydraulics back to full operation. Call Devine Hydraulics, Inc today if you notice one or more of these issues with your hydraulic machinery or equipment.

Share On: